Developed to combine the latest industry technologies with maximum ease of use, McCormick’s high-power open-field tractors in the “X8 VT-Drive” series ensure top operational efficiency even during the most demanding work cycles, delivering significant returns in terms of operating cost containment

The intelligent use of technology is one of the greatest challenges modern society faces. Technical innovations must not only be accessible to everyone—a necessary condition for any technology to become a true social “revolution”—but above all, they must simplify the lives of those who use them daily. Every innovation should therefore be functional to the purpose it was created for, helping users improve their quality of life or work through solutions that are simple and intuitive to use.

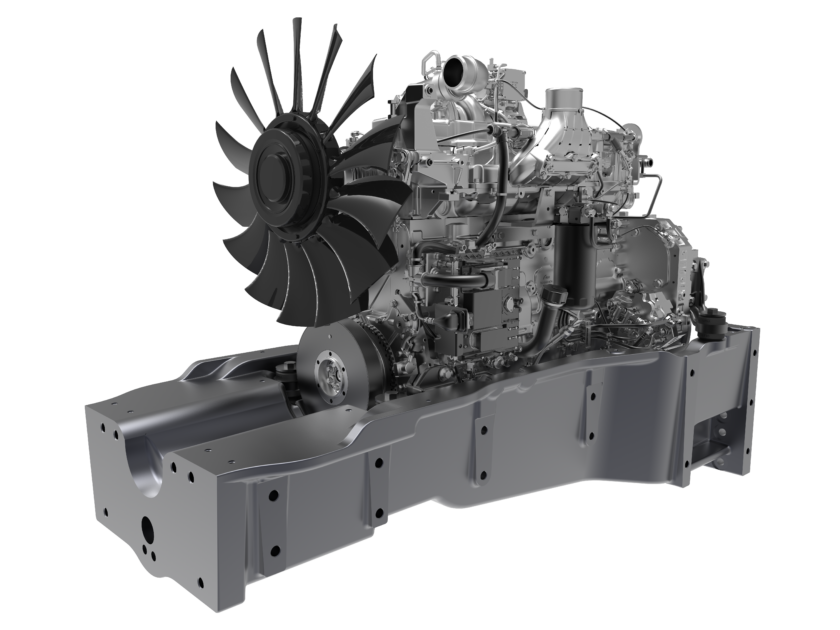

This is the very principle McCormick engineers followed when developing the top-of-the-line “X8 VT-Drive” series. These high-power tractors stand among the most technically advanced in the market today, while also being user-friendly enough for even less experienced users to fully exploit the features the brand offers. The goal is threefold: performance, technology, and ease of use—embodied in two models: the “X8.627 VT-Drive” and the “X8.631 VT-Drive,” delivering maximum outputs of 273 and 313 horsepower respectively. These are tractors designed for heavy-duty road transport and biogas production operations, while also offering competitive power-to-weight ratios for the most demanding open-field applications.

In these demanding scenarios, the VT-Drive continuously variable transmission (CVT) plays a key role in simplifying operation. This transmission combines a hydrostatic module with a four-stage electronically controlled powershift. The hydrostatic module phases out its role at four speed ranges—corresponding to those most used in the field—thus ensuring nearly the same efficiency as traditional powershift transmissions. However, unlike powershift gearboxes, the VT-Drive can continuously decouple ground speed from engine RPM and throttle load.

This feature proves advantageous on the road, where the tractor can cruise at 40 km/h at just 1,300 rpm, and at 50 km/h—where permitted—at only 1,600 rpm. Such flexibility allows the VT-Drive transmission to optimize energy use based on operating conditions, significantly reducing fuel consumption and operating costs.

This goal is further supported by the six-cylinder, 6.7-liter FPT Industrial “N67” engines powering the two X8 VT-Drive models. Certified for Stage V emissions compliance through the use of SCR and DOC systems—without resorting to EGR—they employ high-pressure common rail fuel systems, four-valve-per-cylinder heads with hydraulic tappets, and electronically controlled variable geometry turbochargers. These solutions deliver smooth, linear power curves that reduce fuel consumption even during the most energy-demanding tasks.

To handle high-flow implements, a load-sensing hydraulic system delivers up to 212 liters of oil per minute, available for up to seven auxiliary valves and a rear electronically controlled lift with a maximum capacity of 12,000 kg. A 5,000-kg front lift is also available, likewise electronically controlled. Both front and rear PTOs are electrohydraulically engaged: the front operates at 1,000 rpm, while the rear offers three speeds—540 and 1,000 in ECO mode, and 1,000 rpm in standard configuration.

All functions can be easily managed via the “VT Easy Pilot” joystick installed inside the latest-generation “Clever Cab.” This cab enhances operator comfort even during intensive work shifts thanks to its automatic climate control system and the “DSM Plus” system (Data Screen Manager Plus). DSM Plus combines a 12-inch touchscreen monitor for displaying key operational data with a second 12-inch digital dashboard, navigable via an encoder located on the multifunction armrest.

Sustainability from Every Angle

Technologically advanced to support precision agriculture practices essential for the sustainable development of the farming sector, McCormick’s high-horsepower open-field “X8 VT-Drive” tractors integrate the most modern digital tools aimed at optimizing production cycles.

All of these tools are easily accessible via the “My McCormick” mobile app, which unifies three core platforms:

- McCormick Fleet & Remote Diagnostic Management

- McCormick Efficiency Plan

- McCormick Farm

The Fleet & Remote Diagnostic Management platform uses satellite systems and communication protocols to geolocate machines, monitor their activity in real-time, and assess each unit’s performance and economic returns during any work cycle. Diagnostics can also be conducted remotely to identify problems early and enable quick, targeted maintenance interventions that minimize downtime.

Dealers can also use the app to share event info or special promotions, opening a direct line of communication with customers. Through this channel, users can book appointments, receive personalized offers for tractors, parts, or services, and monitor the scheduled maintenance deadlines for each piece of equipment.

The McCormick Efficiency Plan feature allows users to easily schedule and track routine maintenance. It shows which checks to perform, what preventative work is needed, and which parts are required—parts that can even be ordered directly through the app’s integrated online store. This ensures that users always keep their machines operating at peak efficiency—an essential condition for streamlining operations and controlling costs.

Lastly, the McCormick Farm module is a user-friendly farm management software that helps run agricultural operations with maximum efficiency. Once field maps and crop types are loaded, it assists the operator in planning work routes that minimize compaction and travel time. Based on historical yield data, it optimizes the use of fertilizers by targeting only the areas that need treatment, thereby aligning output with field averages.

The synergy between “McCormick Farm” and the onboard GPS also enables full traceability of operations and yields, giving farmers complete control over their enterprise—without ever stepping down from the tractor. The software tracks stock levels in real time and manages the machinery fleet based on pending jobs. With internet connectivity, it also provides up-to-date weather forecasts and pest alerts, suggesting the best actions to counter potential threats—acting as a true digital agronomic assistant that even manages irrigation, alerts, and equipment servicing.

Its utility extends beyond fieldwork into administrative and managerial tasks, including invoice generation, debit notes, and cost-revenue analysis based on crop-specific comparisons.

Title: The Tractors McCormick X8 Vt-Drive work Hard and consume little

Translation with ChatGPT