Now in their fifth generation, the Krone Big Pack Hdp large square balers offer bale densities that are up to twenty percent higher than industry standards. In the meantime, a new spare parts warehouse has been opened in Spelle

Due to the announced American duties, which have been echoed by the reactions of partner countries and competitors, the global commodities market is in turmoil. Italian agriculture is also affected by this, starting with the straw cereal market. According to Istat, in 2024, 1.177 million hectares of durum wheat were sown in Italy, whose ancestral Italian dependence on imports exposes the Belpaese to international commercial whims.

Another problem is that linked to prices, with durum wheat quoted in spring at a maximum of 310 euros per ton, while it travels around 130 euros per ton, provided they are in top quality square bales. This is precisely the objective that Krone’s large square balers, now in their fifth technological generation and called “BigPack” due to the large dimensions that the bales they process can reach, aim for.

In this sense, there are five basic models, “870”, “890”, “1270”, “1290” and “4×4”, respectively capable of following up bales with fronts of 70×80 centimetres, 90×80, 120×70, 120×90 and 130×120 centimetres with lengths that can range from a minimum of 50 centimetres to a maximum of three metres and twenty centimetres. These differences are then combined with the availability of two different pressing systems, the standard one and the “Hpd” one, an acronym that indicates high density pressing, and two cutting systems for the harvest called “Xc”, with 16 or 26 knives, and “Vc”, modular and capable of operating with 51 blades.

In total, Krone offers 14 models of the “1270” series balers, which also feature the “Multibale” system as standard. This system segments the bales, tying up to nine smaller bales separately and ejecting them as a single large bale. The sub-units can be easily separated on the farm and are easier to handle, especially on small farms and in riding stables.

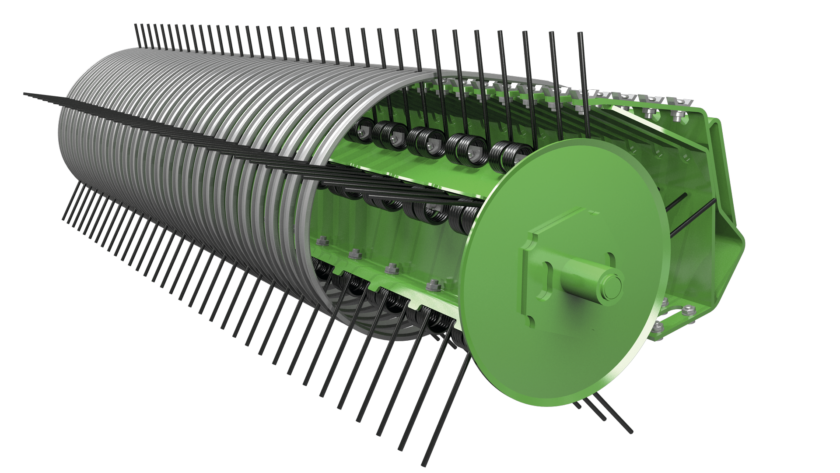

It should be noted that the width of the pick-ups is 235 centimetres for all models except the attack model, “Big Pack 870 Hdp”, which can optionally be equipped with a 195 centimetre wide pick-up. This group, like the larger ones, is part of the “Active EasyFlow” series, free from cams and boasting a high mass conveying capacity thanks to an introduction roller served by five rows of teeth made from special, highly elastic steels.

Technology and reliability

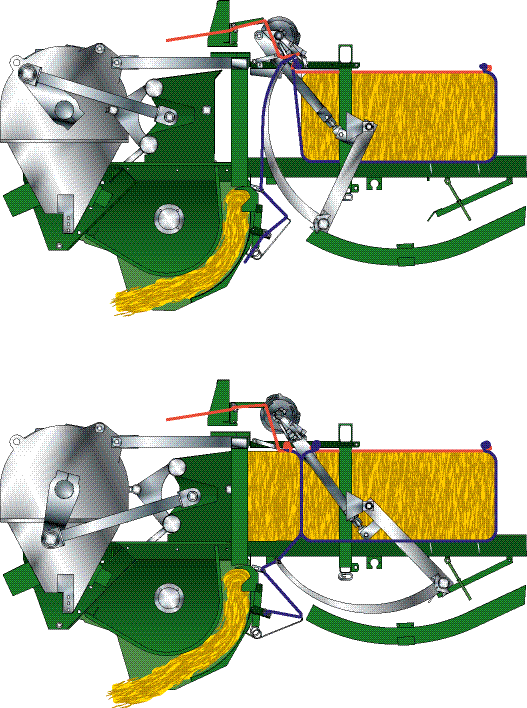

Usable for both straw and forage, the pick-ups ensure fast but progressive transfers of the crop to the compression chamber, avoiding the onset of any blockages thanks to the high rotation speed of the cutting parts and the generous free space at their disposal. An electronically controlled belt drive system also protects the mechanics from unwanted overloads, which intervenes when necessary, leaving the compression piston with the task of producing final weights of the prisms that are approximately twenty percent higher than that of other solutions offered on the market.

This is thanks to a flywheel with a mass of over 600 kilos and the possibility of varying the strokes per minute between 38 and 49 units depending on the volume of the windrow. The efficient double binding systems then come into play to complete the work, made particularly reliable by continuous centralized lubrication supplied as standard. In this way, daily productivity can reach 50 tons compared to the 35-40 offered by other less fast and performing solutions.

Title: Krone Big Pack presses, fifth generation at the top

Translation with Google