Case Ih Axial-Flow 160 and Axial-Flow 260 rotary combines are renowned worldwide for their high operating speeds, achieved while preserving grain, straw, and soil. Less known, however, is the exceptional versatility of these machines, allowing a single model to handle virtually any crop type

Introduced at Agritechnica in 2023 and launched on the market last year, the Case IH rotary combines in the “Axial-Flow 160” and “Axial-Flow 260” series have lived up to their reputation as class leaders in working speed.

Alongside this advantage, they also offer maximum care for grain, straw, and soil, as well as unmatched versatility that enables successful operation across all types of harvests.

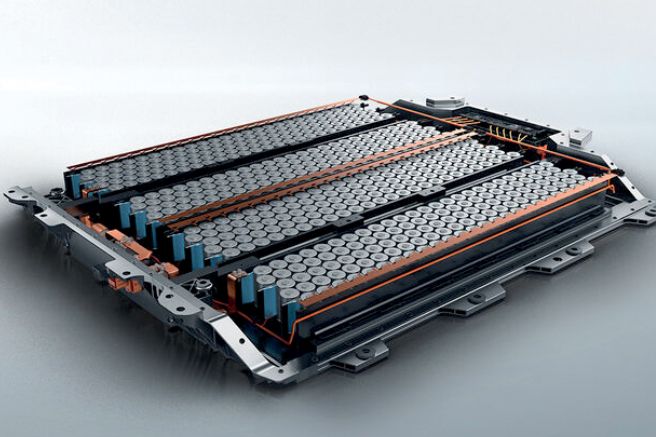

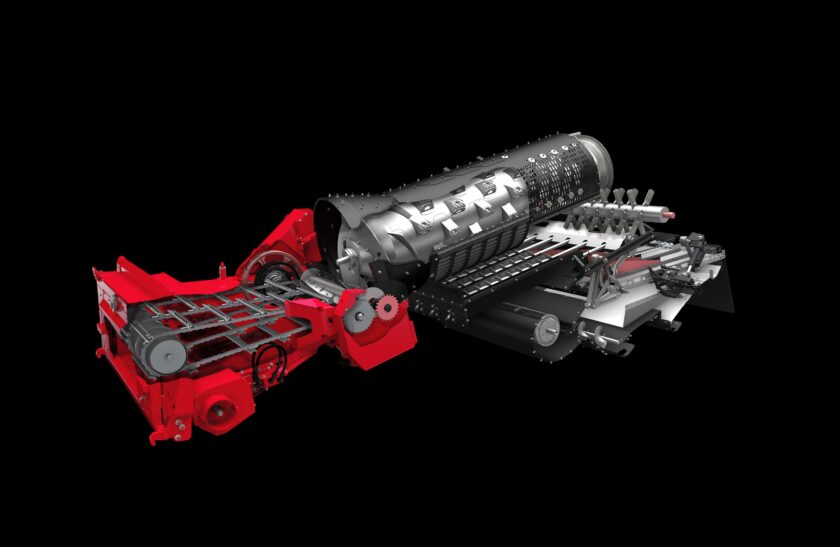

This is made possible by Case IH’s unique separation system, which relies on an axial-flow rotor specifically designed for European crops and operates without a traditional threshing drum. In practice, separation occurs through centrifugal force alone, in a continuous, seamless threshing-separating process. This gentler method preserves the integrity of both grain and straw and enables higher throughput (tons/hour), even with delicate grains.

Contributing to this performance is the “Cross Flow” cleaning system, which engages after separation. It uses a V-shaped blade fan to generate high air volumes and consistent airflow vortices along the full axis of the rotor. Unlike traditional cleaning systems, this design avoids localized air pockets and ensures uniform airflow across the entire underside of the sieves. Fan speed can be adjusted to match grain size, just like the rotor speed, with all these parameters automatically managed and optimized by the “Harvest Command” system.

Also “Harvest Command”

This intelligent automation relies on 16 different sensors, including two exclusive to Case Ih: one that monitors sieve pressure and a multispectral camera that analyzes processed material in real time. “Harvest Command” fully automates combine operation, allowing the operator to focus solely on supervision. If desired, manual adjustments can still be made via the onboard console or the “Pro 700” touchscreen monitor.

In practice, the “Harvest Command” platform requires only two manual actions from the operator: adjusting the concave clearance and activating the unloading auger. Everything else is handled automatically, from ground speed (adapted to crop load) to fan speed, sieve openings, and rotor cage vane positioning. As a result, “Axial-Flow” combines are exceptionally user-friendly when relying on the onboard system, which integrates a comprehensive suite of digital tools to simplify every stage of work.

In addition to the aforementioned “Harvest Command,” these tools include “AccuSync” and “AccuGuide” for autonomous in-field driving, even at headlands, and “Field Ops,” which supports fleet management—including mixed-brand fleets—and comprehensive farm data oversight.

A dedicated control unit manages the powertrain, which uses FPT Industrial “Cursor” series engines. The “AF 6160” and “AF 7160” models feature Cursor 9 engines, while the high-end “AF 8260” and “AF 9260” are equipped with Cursor 13 and Cursor 16 units, respectively. The mid-range “AF 7260” comes with a Cursor 11 engine. Each engine designation reflects nominal displacement rather than power output, which ranges from 400 to 634 horsepower—achieved with minimal fuel consumption and in full environmental compliance.

This eco-friendly performance is due not only to Stage V-compliant engines that operate without EGR systems, but also to the option of suspended front tracks paired with all-wheel drive. These tracks can reduce ground pressure by up to 35%, enhance traction. Feature a hydraulic suspension system with two 40 mm travel cylinders in both directions to evenly distribute pressure over the contact patch, improving stability on uneven terrain.

Rubber tracks also allow installation of a rear-wheel drive system, especially valuable on soft ground or slopes. In such conditions, the standard “Terrain Tracker” system is highly appreciated—it keeps the header parallel to the ground and maintains the operator’s preset cutting angle.

Another noteworthy feature is the ability to select the final straw residue treatment from four different modes: depositing straw on the field or in windrows for later collection, or chopping and spreading it across widths exceeding 12 meters.

American-Style Luxury

Combines often operate continuously, stopping only for refueling and maintenance. That’s why operator comfort is critical—and the “Axial-Flow” series excels in this regard. These machines feature spacious, bright cabs available in two configurations: “Deluxe” and “Luxury.” Both offer exceptional comfort, with the “Luxury” package standing out for its refined details, such as premium leather upholstery and a semi-active air-suspended driver’s seat with ventilated and heated cushions and backrest.

Standard features include a retractable refrigerator, electrically adjustable and heated mirrors, and an adjustable control console that ensures all functions are within easy reach. This includes the multifunction joystick, which allows full manual control of both the machine and the header if desired.

Title: Case Ih Axial Flow rotary combine harvesters: fast, virtuous and versatile

Transaltion with ChatGPT