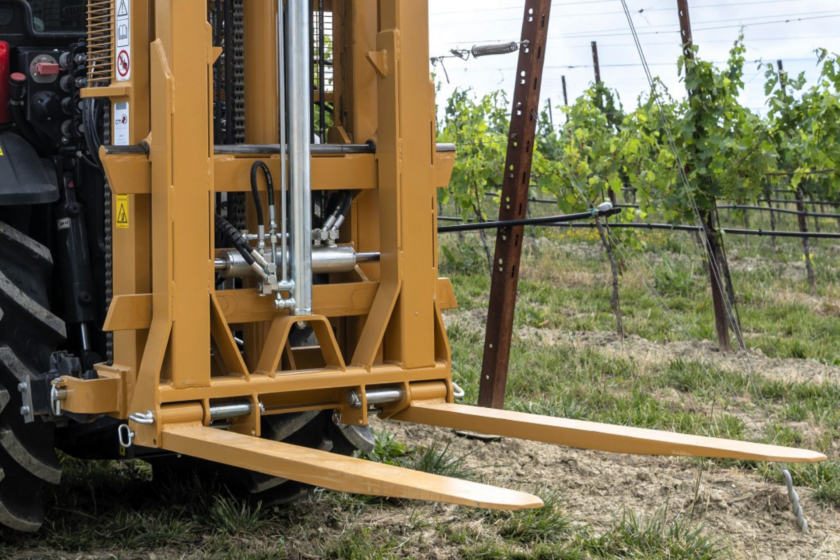

With capacities of 10 and 16 quintals, the three-stage hydraulic elevators 10 Tbcl and 16 Thad by Cm are designed to meet the application needs of medium and large-sized wine companies that intend to speed up the timing related to harvest logistics.

In recent years, handling activities have become a priority issue for wine companies. The increasingly variable climatic conditions, characterized by violent and sudden adverse weather conditions, risk reducing the time windows useful for optimal grape harvesting during each harvest.

To protect company profitability, it is therefore necessary to carefully plan the harvesting phase and, above all, speed up the transport and storage activities of the product. Needs that the triplex hydraulic elevators “10 Tbcl” and “16 Thad” by Cm specifically address, the best-selling equipment in the segment of the Ravenna company, based on a design and development aimed at privileging the speed and safety of handling activities in the wine sector through technical solutions that can be adapted based on individual application needs.

Cm triplex elevators, reliability from Romagna

High customization possibilities, therefore, a prerogative that the Romagna brand has always offered to its customers, also aimed at emphasizing a construction quality derived from the use of hot-rolled steel profiles in the manufacturing phase. Thanks to this, even the compact version “10 Tbcl” ensures the complete and safe usability of the ten quintals of maximum capacity which in practice orients its mission profile towards those medium and small-sized wine companies that need a light and easy-to-handle elevator to make movements faster in areas characterized by limited maneuvering space.

In such contexts, it is also possible to benefit from complete visibility of the load thanks to a strong structure of two lateral lifting cylinders, instead of the classic single central cylinder, which control the lifting and lowering in such a way as to ensure full control of the activity in progress. This therefore results in maximum operational safety, a quality also shared by the “16 Thad” model with a capacity of 16 quintals which addresses the needs of more structured companies or those requiring equipment specifically designed to operate in canopy vineyards.

Equipment with greater efficiency

This is thanks in particular to a free lift of 200 millimetres which allows only the forks to be lifted, without the equipment increasing its vertical bulk compared to the rest position, while a double-acting lifting cylinder is responsible for maintaining the constant lifting and lowering speed of the forks themselves, making the entire process free from the risk of “jerking”.

Common to both Cm triplex elevators from the Romagna-based company is the possibility of equipping the equipment with optional hydraulically controlled solutions of original Cm design aimed at maximizing the efficiency of the equipment, such as, for example, customizable crate tighteners based on individual operational needs, tippers and frames with tipping containers for grapes.

Title: Cm triplex elevators for viticulture: faster harvests

Translation with Google